Ever wondered why some timber roofs last centuries while others fail within decades? The difference lies in understanding how wood behaves under load and designing accordingly.

I’m going to walk you through everything you need to know about wood roof structures—from basic physics to real-world calculations. By the end, you’ll design timber roofs with confidence.

What Is a Wood (Timber) Roof Structure?

Simply put, it’s your building’s load-carrying skeleton made from timber. Think of it as a funnel system—collecting loads from the roof surface and channeling them safely to the ground.

Key components:

- Rafters: Main load-bearing members (typically 50x150mm to 75x225mm)

- Trusses: Triangulated systems for longer spans (up to 20m+)

- Connections: The critical weak points that often determine capacity

The beauty of timber? It’s got a strength-to-weight ratio of around 140 N·m/kg for C24 grade timber—not far behind structural steel at 180 N·m/kg.

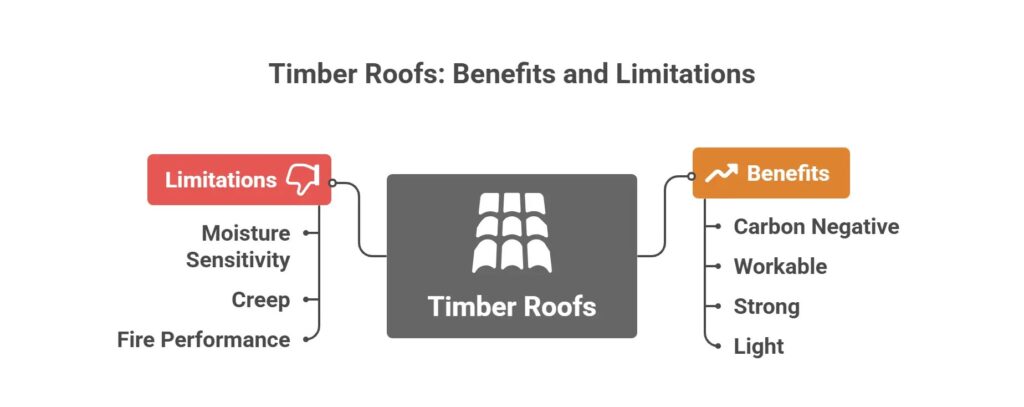

Benefits and Limits of Timber Roofs (Europe)

Why timber works:

- Carbon negative: Stores ~0.9 tonnes CO2 per cubic meter

- Workable: Standard tools, no special equipment needed

- Strong: C24 timber handles 24 N/mm² in bending

- Light: Only 420 kg/m³ compared to concrete at 2400 kg/m³

Where it struggles:

- Moisture sensitivity: Strength drops 25% when moisture exceeds 18%

- Creep: Long-term deflection can double initial values

- Fire performance: Needs 40mm char depth for 60-minute rating

According to Eurocode 5 data, these factors directly influence your design approach.

Loads and Load Paths (Eurocode-Aligned)

Here’s where the rubber meets the road. You need to understand three load types:

Dead Loads (Permanent)

- Timber structure: 0.4-0.6 kN/m²

- Clay tiles: 0.8-1.2 kN/m²

- Metal roofing: 0.15-0.25 kN/m²

- Insulation + sheathing: 0.2-0.3 kN/m²

Snow Loads (Variable)

European ground snow loads vary dramatically:

- Alpine regions: 4-6 kN/m² (Switzerland, Austria)

- Northern Europe: 2-4 kN/m² (Scandinavia)

- Mediterranean: 0.5-1.5 kN/m² (Spain, Italy)

- UK/Ireland: 0.6-1.0 kN/m²

Source: EN 1991-1-3 National Annexes

Wind Loads (Critical for Design)

Wind often governs design, especially uplift. Basic wind speeds:

- Coastal areas: 26-30 m/s

- Inland areas: 22-26 m/s

- Mountain regions: Up to 35 m/s

These translate to pressure coefficients of -1.2 to -2.0 for roof edges and corners.

Statical Systems of Common Timber Roofs

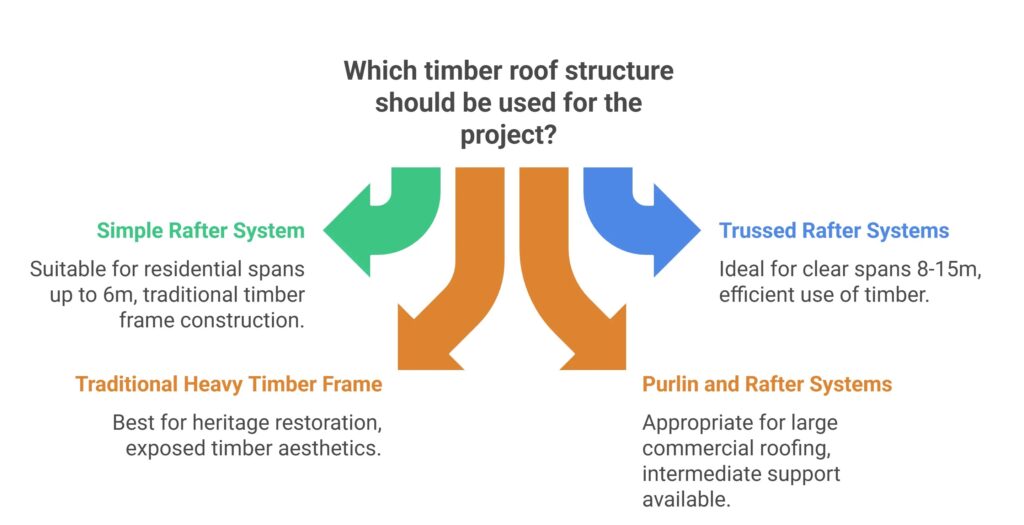

Understanding structural systems helps you choose the right timber roof structure approach for each project:

1. Simple Rafter System (Timber Frame Construction)

Application: Residential spans up to 6m, traditional timber frame construction

Structural behavior: Individual timber rafters act as simply supported beams

Typical sections: 50×200mm sawn lumber at 600mm rafter spacing

Load path: Roof loads → timber rafters → wall plates → load-bearing walls

2. Trussed Rafter Systems (Engineered Timber Trusses)

Application: Clear spans 8-15m, manufactured timber roof trusses

Structural behavior: Triangulated geometry distributes loads through axial forces

Typical spacing: 400-600mm centers for residential timber roofing

Efficiency advantage: 30% less timber volume than equivalent rafter system

3. Traditional Heavy Timber Frame

Application: Heritage restoration, exposed structural timber aesthetics

Structural behavior: Post-and-beam load transfer with large timber sections

Typical sections: 200×300mm principal rafters, mortise and tenon joinery

4. Purlin and Rafter Systems

Application: Large commercial timber roofing, intermediate support available

Structural behavior: Two-way spanning system reduces individual member sizes

Benefit: Allows smaller rafter sections through load sharing between structural elements

Anatomy: Components and Their Roles

Understanding each component’s job helps you design better connections:

Ridge beam vs ridge board:

- Ridge beam: Carries load, needs structural support

- Ridge board: Just connects rafters, no structural role

Wall plates:

- Distribute point loads from rafters

- Must resist horizontal thrust (can be 40% of vertical load)

- Typical size: 100x75mm minimum

Collar ties vs. ceiling joists:

- Collar ties: Reduce rafter span, positioned at upper 1/3

- Ceiling joists: Tie walls together, resist thrust completely

How to Analyze a Simple Rafter Roof (Step-by-Step)

Let’s work through a real example:

Given: 8m span, 35° pitch, 600mm spacing, Munich location

Step 1: Load Calculation

Dead load: 1.2 kN/m² (structure + tiles)

Snow load: 1.85 kN/m² (Munich = zone 2)

Wind load: Check for uplift

Step 2: Convert to Rafter Loads

Rafter spacing = 0.6m

Total load per rafter = (1.2 + 1.85) × 0.6 = 1.83 kN/m

On slope = 1.83 ÷ cos(35°) = 2.23 kN/m

Step 3: Structural Analysis

Span along rafter = 8m ÷ cos(35°) = 9.76m

Maximum moment = wL²/8 = 2.23 × 9.76²/8 = 26.5 kNm

Step 4: Member Design

Required section modulus = M/fb = 26,500/24 = 1,104 cm³

Try 75x225mm: Actual Wz = 1,266 cm³ ✓

This systematic approach works for any simple rafter system.

How to Analyze a Trussed Rafter Roof

Trusses work differently—internal forces matter more than bending moments.

Key insight: Each member sees either pure compression or tension.

Analysis Steps:

- Determine truss geometry (pitch, panel lengths)

- Calculate joint loads from tributary areas

- Use method of joints to find member forces

- Check compression members for buckling

- Design connections for calculated forces

Real data: A typical 12m span truss with 35° pitch and 2.4kN/m loading produces:

- Top chord compression: ~15kN per member

- Bottom chord tension: ~25kN

- Maximum web force: ~8kN

Most truss failures occur at connections, not in members themselves.

Connections and Joints (Design Essentials)

This is where most engineers get it wrong. Connections often govern capacity, especially under uplift.

Nailed Connections

Typical capacity: 1.2kN per 3.1mm diameter nail (C24 timber)

Critical factors:

- Edge distance: 5 × nail diameter minimum

- Spacing: 10 × diameter for full capacity

- Moisture content effects: -25% capacity if >18% MC

Hurricane Ties

Essential in wind zones. A typical galvanized hurricane tie provides:

- Uplift capacity: 3.5-6.2kN depending on model

- Installation: 10 nails minimum, specific pattern required

Data source: Simpson Strong-Tie technical specifications

Bolted Connections

Higher capacity but more complex:

- 12mm bolt in C24: ~8kN parallel to grain

- 16mm bolt in C24: ~14kN parallel to grain

- Requires washers and proper edge distances

Roof Diaphragms, Bracing, and Uplift

Your roof needs to act as a unified system, not just individual members.

Diaphragm Capacity

18mm OSB sheathing with proper nailing provides ~3kN/m shear capacity—adequate for most residential wind loads.

Bracing Requirements

Permanent bracing: Structural sheathing or diagonal strapping Temporary bracing: Essential during construction—most failures occur here

Uplift Design

Critical zones:

- Roof edges: -1.6 pressure coefficient

- Corners: -2.0 pressure coefficient

- Ridge: -0.8 pressure coefficient

Standard gravity connections often can’t handle these forces. Proper storm damage assessment frequently reveals connection failures rather than member overstress.

Roof Coverings and Sheathing: Structural Impacts

Your covering choice directly affects structural design:

Heavy Coverings (Clay Tiles)

- Point loads: 150-200N per tile

- Total load: 0.8-1.2 kN/m²

- Deflection limits: L/500 to prevent tile cracking

Light Coverings (Metal)

- Dead load: Only 0.15-0.25 kN/m²

- Uplift critical: Must resist -2.0kN/m² minimum

- Less lateral support: Check compression member buckling

Understanding modern roofing materials helps optimize your structural design.

Bearings and Supports into Walls/Frames

The interface between roof and walls needs careful attention.

Bearing Length Requirements

Minimum bearing: 100mm for loads up to 10kN per rafter Compression perpendicular to grain:

- C24 timber: 2.5 N/mm² basic value

- With load distribution: Up to 10 N/mm² possible

Connection to Different Wall Types

Masonry walls: Need wall plates and proper DPC details Timber frame: Direct connection possible but watch thermal bridging

Steel frame: Use specialized brackets for differential movement

The complete guide to roof anatomy shows how these connections integrate with other building systems.

Worked Example Outline (Rafter Roof, Eurocode)

Here’s a condensed real-world example:

Project: Single-family house, Frankfurt, Germany

- Span: 9.2m

- Pitch: 40°

- Spacing: 600mm centers

- Material: C24 GL timber

Loads:

- Dead: 1.4 kN/m² (concrete tiles + structure)

- Snow: 0.85 kN/m² (Frankfurt zone 1)

- Wind: 0.8 kN/m² (suburban location)

Results:

- Required rafter: 75x250mm

- Maximum deflection: 28mm (L/350 – acceptable)

- Connection: 6No. hurricane ties per rafter

- Cost impact: +15% vs. standard nailed connection

This level of detail gives you confidence in your design decisions.

Tools, Templates, and References

Essential Software:

- Eurocode compliance: SCIA Engineer, Dlubal RFEM

- Timber-specific: SAPIR-TIMBER, Teknos

- Free options: Frame3DD with manual Eurocode checks

Key References:

- Eurocode 5 (EN 1995) – The definitive standard

- STEP Timber Engineering manuals – Practical guidance

- National timber associations – Local detailing requirements

Design Aids:

- Span tables for common sections and loads

- Connection capacity tables

- Maintenance scheduling templates

The key is building your reference library early and updating it regularly as codes evolve.

Conclusion

Wood roof structures aren’t complex—they just require systematic thinking. Understand your loads, trace your load paths, and respect timber’s unique properties. The material has carried roofs successfully for millennia. Your job is applying modern engineering principles to this time-tested approach.

Start with simple projects, build your confidence, and always remember: when in doubt, the connection usually governs.

Frequently Asked Questions

What timber grade should I specify for roof structures?

C24 is standard for structural applications in Europe. It provides 24 N/mm² bending strength and good availability. C16 works for lighter loads but saves minimal cost. GL24h glulam offers higher strength for engineered applications but costs 2-3x more.

How do I handle large deflections in timber roofs?

Pre-cambering works for predictable loads—typically 1.5x calculated deflection. For existing roofs showing excessive sag, sistering new members alongside existing ones often proves more economical than replacement. Always check if deflection is ongoing (structural issue) or stabilized (aesthetic only).

What’s the most common failure mode in timber roofs?

Connection failure under uplift loads, particularly in older construction not designed for modern wind standards. Standard nailed connections often can’t resist the -1.6kN/m² uplift pressures required by current codes. Retrofitting hurricane ties provides significant improvement.

How do moisture conditions affect my design?

Service class determines design values: SC1 (≤20% MC) uses full strength values, SC2 (≤18% most of time) reduces strength 10-15%, SC3 (>18% frequently) requires 25% reduction. Most European residential construction operates in SC1 or SC2 conditions with proper detailing.