When it comes to exterior siding, most homeowners focus on panels, colors, and insulation, but one small component plays a huge role in durability and appearance: aluminum siding corners. These corner pieces protect exposed edges, ensure clean transitions, and help your siding system stand up to wind, rain, and temperature changes. Choosing the wrong type or installing corners incorrectly can lead to loose panels, water intrusion, and premature wear.

In this guide, we’ll explain what aluminum siding corners are, the different types available, how to choose the right ones, and best practices for installation, repair, and maintenance.

What Are Aluminum Siding Corners and Why Do They Matter?

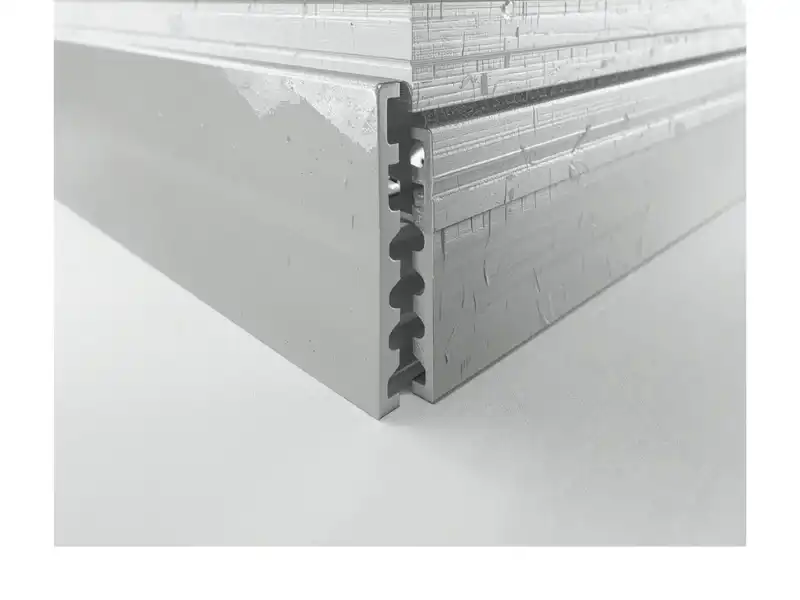

Aluminum siding corners are vertical trim pieces installed where siding panels meet at the edges of a building. They serve both structural and aesthetic purposes, covering raw panel ends while allowing siding to expand and contract properly.

Without properly installed corners, homeowners often face common issues such as:

-

Panels pulling loose during high winds

-

Water seeping behind siding

-

Visible gaps or uneven edges

-

Rust or corrosion at exposed cuts

Quality corner trim helps lock the siding system together while keeping your exterior clean and uniform.

Common Problems Homeowners Face With Corners

Problems usually occur due to poor sizing, improper nailing, or material mismatch. Common issues include:

-

Corners bending or denting easily

-

Paint peeling due to low-quality finishes

-

Buckling caused by a lack of expansion space

-

Mismatched profiles when replacing older siding

Understanding corner types and installation requirements helps prevent these issues long-term.

Types of Aluminum corner trim

Outside Corners vs. Inside Corners

-

Outside corners are used on exterior wall edges where two walls meet outward.

-

Inside corners are installed where walls meet inward, often in recessed areas.

Each type is shaped differently to manage water runoff and siding movement.

Standard Sizes (8″, 9.5″, 12″)

Aluminum siding corners come in multiple heights to match siding exposure:

-

8″ for smaller lap siding

-

9.5″ for standard residential profiles

-

12″ for wider or custom siding applications

Choosing the correct size ensures full panel coverage without gaps.

Smooth vs. Woodgrain Finishes

-

Smooth finish offers a clean, modern appearance.

-

Woodgrain finish mimics traditional wood trim while retaining aluminum durability.y

Matching finishes helps maintain a consistent exterior look.

Low-Profile vs. Standard Profiles

Low-profile corners provide a sleek, minimal appearance, while standard profiles offer deeper coverage and more shadow lines for traditional designs.

Choosing the Right Aluminum Corner Trim

Selecting the right Aluminum siding corner trim involves more than color matching.

Measuring Your Siding Exposure

Always measure the exposed height of your siding panels before purchasing corners. Incorrect sizing can leave visible gaps or restrict panel movement.

Matching Existing Siding

If you’re replacing older corners, match:

-

Color

-

Finish (smooth or woodgrain)

-

Profile depth

This prevents noticeable differences between old and new sections.

Material Thickness Considerations (.019″ Aluminum Standard)

Most residential applications use .019″ aluminum, which balances durability and flexibility. Thinner material dents easily, while thicker options may be harder to install correctly.

Primed vs. Pre-Painted Options

-

Pre-painted corners save time and offer factory-applied finishes

-

Primed corners allow custom color matching but require proper painting

Installation Guide

Tools and Materials Needed

-

Tin snips

-

Measuring tape

-

Level

-

Aluminum nails

-

Hammer or siding nailer

Step-by-Step Installation Process

-

Measure and cut corners to length

-

Position the corner plumb and level

-

Secure from top to bottom

-

Slide siding panels into the corner channel

Proper Nailing Techniques

Never nail corners tightly. Nails should be centered in the slot and left slightly loose to allow movement.

Expansion Gap Requirements

Always leave expansion space at the top and bottom to accommodate temperature changes and prevent warping.

Replacement and Repair

When to Replace vs. Repair

Replace corners if they are:

-

Severely bent or cracked

-

Rusted through

-

Pulling away from the wall

Minor dents or paint issues can often be repaired instead.

How to Remove Damaged Corners

Carefully loosen siding panels, remove fasteners, and slide the damaged corner out without bending surrounding panels.

Common Installation Mistakes to Avoid

-

Over-nailing

-

Usinan g incorrect corner size

-

Ignoring expansion gaps

-

Mixing incompatible profiles

Avoiding these mistakes extends the life of your siding system.

Where to Buy & Cost

Top Retailers Comparison

Aluminum siding corners are commonly available at:

-

Home improvement stores

-

Siding supply distributors

-

Online building material retailers

Average Pricing

Prices typically range from $10 to $25 per piece, depending on size, finish, and thickness.

Bulk vs. Individual Purchase Options

Buying in bulk often reduces per-unit cost and ensures consistent color matching across your project.

Maintenance Tips

How to Prevent Corners From Coming Loose

-

Inspect annually

-

Check fasteners after storms

-

Address movement early

Painting and Finishing

Use exterior-grade paint designed for aluminum if repainting is needed.

Weather Protection

Properly installed aluminum siding corners resist moisture, UV exposure, and freeze-thaw cycles with minimal upkeep.

Final Thought

Though often overlooked, aluminum siding corners play a critical role in protecting your home’s exterior and maintaining a polished appearance. By choosing the correct type, installing it properly, and performing basic maintenance, homeowners can avoid costly repairs and extend the life of their siding. Whether you’re installing new siding or upgrading old trim, investing in quality corner components always pays off in durability and curb appeal.

If you’re unsure which corner profile is right for your home or need professional help with installation or replacement, contact us to discuss your siding needs and get expert guidance you can trust.

Join Our Community

Join our community on Facebook, and don’t forget to subscribe to us on YouTube for new content each week.

FAQs

1. What are Aluminum exterior corner trim used for?

Aluminum siding corners protect exposed siding edges, allow expansion, prevent water intrusion, and create clean, finished exterior transitions.

2. What size Aluminum corner channels do I need?

Most homes use 8″, 9.5″, or 12″ corners, depending on siding exposure and profile depth. Accurate measurement is essential.

3. Why do Aluminum corner pieces for siding come loose?

Loose corners are usually caused by over-nailing, incorrect sizing, or failure to allow expansion and contraction.

4. Can Aluminum exterior corner trim be repaired?

Minor dents or paint issues can be repaired, but severely bent, rusted, or detached corners should be replaced.

5. How long does aluminum exterior corner trim last?

With proper installation and basic maintenance, aluminum siding corners can last several decades without structural failure.