When installing a steel roof, the panels often steal the spotlight, but the real heroes working behind the scenes are the trim pieces. Trim for steel roofing is the collection of specialized metal components that seal edges, transitions, and joints where your roof meets walls, valleys, and eaves. Without proper trim, even the highest-quality steel panels can’t protect your building from water infiltration and weather damage.

The critical role trim plays in preventing leaks and water damage cannot be overstated. Every edge, seam, and transition point on your roof represents a potential entry point for moisture. Quality trim pieces create watertight barriers at these vulnerable locations, directing water away from the building envelope and protecting the underlying structure from rot, mold, and costly repairs.

Beyond functionality, trim also dramatically enhances your roof’s curb appeal. Clean, professionally installed trim pieces give your steel roof a finished, polished appearance that speaks to quality craftsmanship. The right trim transforms a collection of metal panels into a cohesive, attractive roofing system that can last 40 years or more.

What is Trim for Steel Roofing?

Trim for steel roofing refers to the pre-formed metal pieces designed to finish edges, seal transitions, and manage water flow on metal roofing systems. These components serve three primary functions: water management, weatherproofing, and aesthetics. Each piece is strategically shaped to direct water away from vulnerable areas while creating clean visual lines.

Many people confuse trim with flashing, but there’s an important distinction. While flashing specifically refers to waterproofing at transitions and penetrations (like chimneys or skylights), trim encompasses a broader category that includes both functional water management pieces and decorative finishing components. Some pieces, like sidewall flashing, serve dual purposes and fall into both categories.

Building codes in most jurisdictions require proper trim installation as part of a complete roofing system. These requirements recognize that trim isn’t optional—it’s an essential component that determines whether your roof will perform as designed or become a source of chronic problems.

Essential Types of Trim for Steel Roofing

Understanding the different trim pieces and their specific roles helps you ensure nothing gets overlooked during installation.

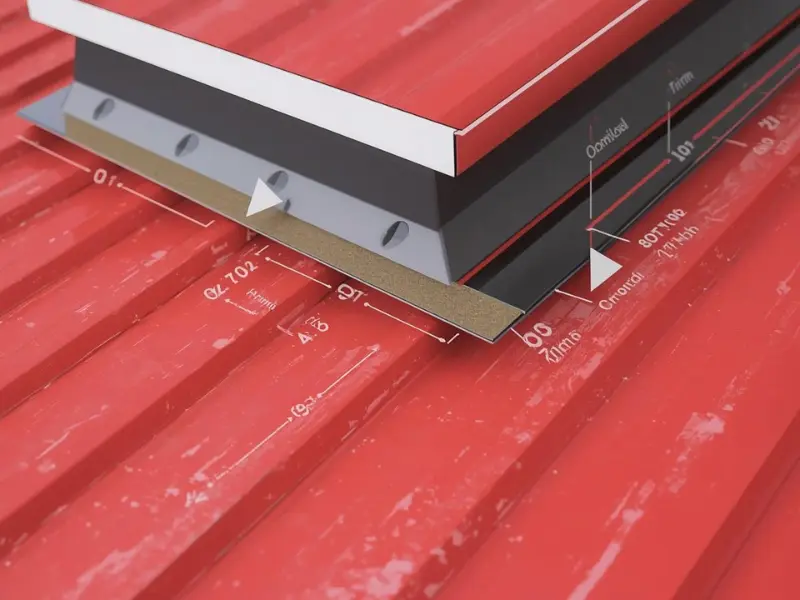

Eave Trim installs along the bottom edge of your roof where panels begin. This critical component catches water running off the panels and directs it into gutters or away from the fascia board. Properly installed eave trim prevents water from wicking back under the roof edge and damaging the roof deck or fascia.

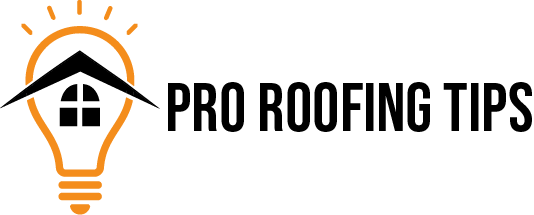

Gable/Rake Trim protects the sloped edges of your roof where panels end at the gable. This trim prevents wind-driven rain from getting under the roof edges during storms. It also gives the roofline a clean, finished appearance when viewed from the side.

Ridge Cap seals the peak where two roof slopes meet at the top. Beyond keeping water out, many ridge cap designs incorporate ventilation features that allow hot air to escape from the attic while preventing rain and snow from entering. This dual functionality makes ridge cap selection particularly important.

Valley Trim manages water where two roof slopes converge, creating a channel that handles some of the highest water volumes on your roof. Valley trim must be wide enough and properly shaped to handle heavy rainfall without overflowing.

Sidewall/Endwall Flashing creates waterproof transitions where your roof meets vertical walls. This trim typically features a step-down design that tucks under siding while overlapping roof panels, ensuring water can’t penetrate the joint.

Drip Edge extends beyond the fascia to direct water away from the building. This simple component prevents water from running down the fascia board or wicking back under the roof edge—two common causes of wood rot and ice dam formation.

Base Trim connects your metal roofing or siding to the foundation, creating a weather-resistant transition that protects the vulnerable area where your building meets the ground.

Corner Trim provides finishing touches at inside and outside corners, particularly important for buildings with metal siding. These pieces create professional-looking corners while sealing gaps where two walls meet.

Z-Trim/Closure Trim fills gaps between metal panels and solid surfaces, preventing pest infiltration while blocking wind-driven rain. These pieces are essential for maintaining the thermal envelope of your building.

Materials and Specifications

The gauge thickness of trim for steel roofing directly impacts its durability and performance. Common gauges include 24-gauge (thickest and most durable), 26-gauge (standard for most residential applications), and 29-gauge (lighter weight, typically used for less critical trim pieces). Thicker gauges resist denting, oil-canning, and wind damage better than thinner materials.

Steel types and coating options affect both longevity and appearance. Galvanized steel offers basic corrosion protection, while Galvalume (aluminum-zinc alloy coating) provides superior rust resistance, particularly important in coastal or high-humidity environments. Premium coatings like PVDF (Kynar) resist fading and chalking far better than standard polyester finishes.

Color matching with your roof panels creates a cohesive appearance. Most manufacturers offer trim in colors that match their panel lines, though exact matches can vary between production runs. For the most seamless look, order trim and panels together from the same manufacturer.

Yield strength considerations matter for structural performance. Higher yield strengths (80,000 PSI) provide better dent resistance and maintain shape under stress, while standard commercial-grade materials (50,000 PSI) work well for most residential applications. Economy-grade trim (37,000 PSI) may be suitable for non-critical applications but lacks the durability of higher-grade options.

Custom versus standard trim shapes affect both price and performance. While standard profiles work for most situations, custom-bent trim ensures perfect fits for unusual roof configurations or specific aesthetic requirements.

Choosing the Right Trim for Steel Roofing

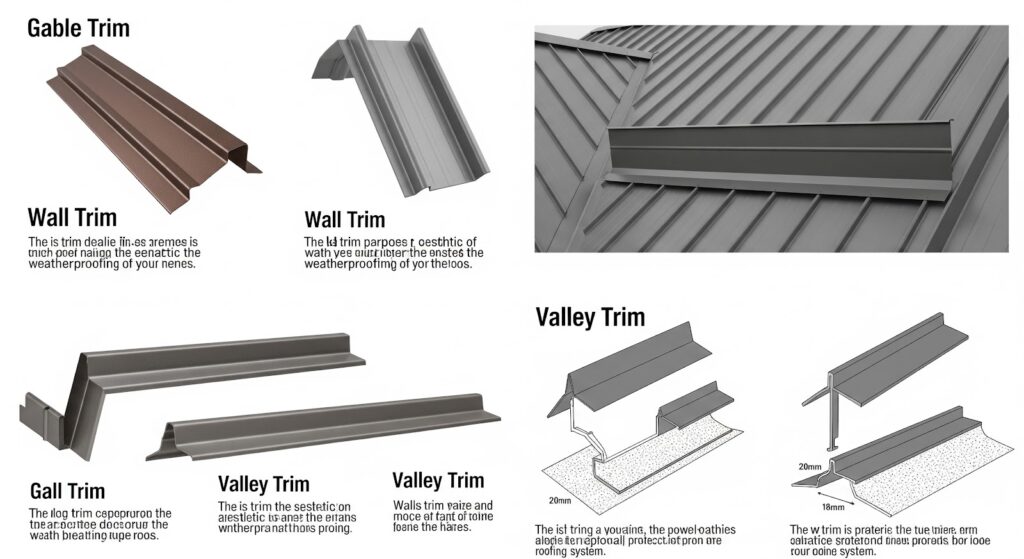

Matching trim to your panel type is essential for proper function. Exposed fastener systems typically use simpler trim profiles with overlapping flanges designed to accommodate the panel ribs. Standing seam systems require specialized trim that works with concealed fastener clips and allows for panel expansion and contraction.

Residential applications typically use lighter-gauge materials and prioritize aesthetics, while commercial and post-frame buildings often require heavier-gauge trim that can span longer distances and withstand higher wind loads. Agricultural buildings may prioritize function and durability over appearance.

Climate and weather considerations should guide your material selection. Coastal areas demand superior corrosion resistance, northern climates benefit from ice-dam-preventing details, and high-wind regions require heavier gauges and additional fastening.

Roof pitch requirements affect trim design and installation methods. Low-slope roofs (below 3:12 pitch) require wider trim pieces with longer overlaps to prevent water infiltration, while steep-slope roofs can use standard profiles.

Cost Guide

Price ranges per linear foot vary significantly by trim type and material quality. Standard eave trim typically costs $2-4 per linear foot, while specialty pieces like custom valley trim may run $6-10 per linear foot. Ridge cap generally falls in the $3-6 range, depending on whether it includes ventilation features.

Labor versus material costs split roughly 60/40 on most trim installation projects, with skilled installers charging $50-100 per hour depending on your location. Complex installations with multiple transitions or custom trim pieces push labor costs higher.

Custom trim pricing adds 30-60% to material costs but ensures perfect fits for unusual situations. For projects with non-standard angles or unique architectural features, custom trim often proves more cost-effective than attempting to adapt standard pieces.

Budgeting tips: Order 10-15% extra material to account for cuts and mistakes, buy all trim pieces at once to ensure color matching, and prioritize quality over price for critical water management areas like valleys and eaves.

Where to Buy Trim for Steel Roofing

Buying direct from manufacturers often provides the best prices and widest selection, particularly for large projects. Major metal roofing manufacturers sell trim alongside their panel products, ensuring perfect compatibility and color matching.

Online sources offer convenience and competitive pricing, but make it difficult to verify quality before purchase. Reputable online suppliers should provide detailed specifications, gauge information, and offer warranties.

Local metal roofing suppliers provide the advantage of seeing materials in person, getting immediate delivery, and establishing relationships for future needs. Many offer custom bending services that can create trim pieces while you wait.

What to look for in quality trim: consistent coating coverage with no bare spots, crisp bends without cracking or distortion, proper gauge thickness (verify with a micrometer if necessary), and manufacturers who stand behind their products with meaningful warranties.

Final Thoughts

The importance of proper trim selection extends far beyond avoiding leaks; it determines whether your steel roofing investment delivers decades of reliable performance or becomes a source of ongoing problems. Quality trim pieces, properly selected and expertly installed, transform good roofing panels into complete weather-protection systems.

Every roof is unique, with specific requirements that vary based on its design, climate, and building type. If you’re planning a steel roofing project, don’t leave trim selection to chance. Contact us today to speak with a qualified metal roofing professional who can assess your specific needs, recommend appropriate trim for steel roofing applications, and ensure proper installation. The modest investment in expert consultation now can prevent expensive repairs and premature roof failure down the road.

Join Our Community

Join our community on Facebook, and don’t forget to subscribe to us on YouTube for new content each week.

FAQs

1. What is trim for steel roofing?

Trim is pre-formed metal pieces that seal edges, transitions, and joints on your steel roof, preventing water infiltration and providing a finished appearance.

2. What gauge thickness is best for roof trim?

A: 26-gauge is standard for residential roofs, 24-gauge for commercial or harsh climates, and 29-gauge for decorative, non-critical applications only.

3. How much does steel roofing trim cost?

Standard trim costs $2-4 per linear foot, specialty pieces $6-10, and ridge cap $3-6 per foot, plus labor, which typically runs 60% ofthe total project cost.

4. Can I install trim for steel roofing myself?

While possible for experienced DIYers, professional installation is recommended to ensure proper waterproofing, avoid leaks, and maintain manufacturer warranties.

5. What’s the most important trim piece on a steel roof?

Valley trim and eave trim are most critical as they handle the highest water volumes and protect vulnerable roof edges from moisture damage.