Confused about metal roofing thickness? You’re not alone! Walk into any building supply store and ask about 24 gauge thickness versus 26 gauge steel thickness, and you’ll likely get conflicting advice that leaves you more puzzled than informed. Here’s the truth: understanding metal gauge thickness isn’t just about numbers—it’s about making smart decisions that protect your investment for decades.

Whether you’re wondering how thick is 26 gauge sheet metal or trying to determine what is the best gauge metal roof for your climate, this comprehensive guide cuts through the confusion with clear, practical information that helps you choose confidently. Get ready to become a metal roofing gauge expert!

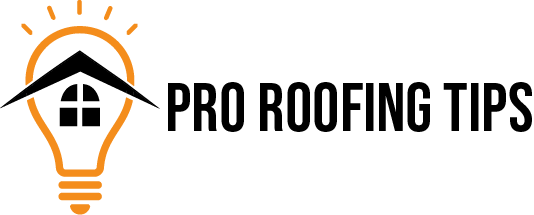

Find the Metal Gauge System: Why Smaller Numbers Mean Thicker Metal

The metal gauge system seems backwards to most people, and honestly, it is! Is 22 gauge thicker than 24? Yes, absolutely! In the gauge system, smaller numbers indicate thicker metal, while larger numbers mean thinner material. This counterintuitive system dates back to wire manufacturing, where more drawing operations (higher numbers) created thinner wire.

Understanding this backwards system becomes crucial when comparing options for your roofing project. 22 gauge thickness provides more durability than 24ga steel thickness, which in turn offers more strength than 26 gauge thickness. This hierarchy affects everything from weather resistance to longevity, making gauge selection one of your most important decisions.

Metal roof thickness directly impacts performance characteristics including dent resistance, thermal expansion behavior, and structural load capacity. Thicker gauges cost more initially but often provide better long-term value through enhanced durability and reduced maintenance requirements. Smart buyers balance initial costs against long-term performance when selecting appropriate gauge levels.

Detailed Thickness Measurements for Common Roofing Gauges

Premium Thickness Options

How thick is 22 gauge metal? This premium gauge measures approximately 0.0299 inches thick, making it the heaviest option commonly used for residential and light commercial applications. Thickness of 22 gauge steel provides exceptional dent resistance and structural strength that justifies its premium pricing for demanding applications.

Buildings in hail-prone areas benefit significantly from 22 gauge construction, as the additional thickness dramatically reduces denting from impact damage. The extra material also provides better thermal mass, reducing expansion and contraction cycles that stress fasteners and sealants over time.

How thick is 22 gauge becomes particularly important for standing seam applications where panel strength affects both appearance and performance. Heavier gauges maintain straighter panel lines and resist oil-canning (waviness) that can detract from premium installations.

Standard Commercial Options

24 gauge thickness measures approximately 0.0239 inches, representing the sweet spot between cost and performance for most commercial applications. This gauge provides excellent durability while maintaining reasonable material costs that keep projects within budget constraints.

How thick is 24 gauge steel makes it suitable for most residential applications and many commercial installations where extreme weather resistance isn’t required. The 24 gauge option handles normal wind loads, thermal cycling, and moderate hail impact while providing decades of reliable service.

How thick is 24 gauge metal affects installation considerations, as the material offers good workability for field forming and cutting while maintaining sufficient strength for structural applications. Contractors appreciate the balance between durability and ease of handling that 24 gauge provides.

Economy Residential Choices

26 gauge steel thickness measures approximately 0.0179 inches, making it the thinnest gauge commonly recommended for residential roofing applications. How thick is 26 gauge sheet metal determines its suitability for budget-conscious projects where initial cost takes priority over maximum durability.

26 gauge thickness works well for residential applications in moderate climates where severe weather exposure is uncommon. The thinner material costs significantly less than heavier gauges while still providing adequate protection for most homes.

26 ga thickness requires more careful handling during installation due to reduced dent resistance and structural strength. Professional contractors adjust their techniques when working with thinner gauges to prevent damage during installation while ensuring proper performance.

26 gauge metal thickness affects thermal expansion characteristics, with thinner materials experiencing more movement during temperature changes. Installation details must accommodate this increased movement to prevent fastener problems and premature failure.

Specialty Light-Duty Applications

29 gauge thickness measures approximately 0.0135 inches, representing the minimum thickness suitable for roofing applications. How thick is 29 gauge steel limits its use to specific applications where weight and cost considerations outweigh durability requirements.

How thick is 29 gauge metal makes it suitable primarily for agricultural buildings, temporary structures, or budget-conscious residential applications in mild climates. The reduced material thickness significantly lowers costs while providing basic weather protection.

Metal roof thickness at the 29 gauge level requires careful consideration of structural support, wind loads, and installation techniques. Professional contractors understand the limitations and adjust their approaches accordingly to ensure acceptable performance.

Comprehensive Metal Roofing Gauge Thickness Chart

Understanding Metal Roofing Gauge Thickness chart information helps you compare options systematically rather than relying on sales presentations that may emphasize cost over performance. Here’s how different gauges stack up:

22 Gauge (0.0299″)

- Premium residential and commercial applications

- Exceptional hail and impact resistance

- Superior structural strength and longevity

- Higher cost but maximum durability

- Best choice for severe weather climates

24 Gauge (0.0239″)

- Standard commercial and premium residential

- Good balance of cost and performance

- Adequate weather resistance for most climates

- Moderate pricing with solid durability

- Most popular choice for quality installations

26 Gauge (0.0179″)

- Economy residential and light commercial

- Basic weather protection at lower cost

- Suitable for moderate climate conditions

- Budget-friendly option with acceptable performance

- Requires careful installation and maintenance

29 Gauge (0.0135″)

- Agricultural and temporary structures

- Minimal weather protection at lowest cost

- Limited to mild climate applications

- Economy option with basic functionality

- Not recommended for permanent residential use

Determining What Gauge Steel Roofing Works Best

What gauge is steel roofing for your specific application depends on multiple factors including climate conditions, building use, budget constraints, and long-term performance expectations. Understanding these factors helps you select the optimal gauge for your unique situation.

Climate considerations significantly influence gauge selection, with severe weather areas requiring heavier gauges for adequate protection. How thick is 26 gauge metal roofing may suffice in mild climates but prove inadequate where hail, high winds, or extreme temperature cycling occur regularly.

Building use affects gauge requirements, with commercial and industrial applications typically requiring heavier gauges than residential installations. High-traffic roof areas, equipment mounting points, and structural considerations often dictate minimum gauge requirements regardless of budget preferences.

What is the best gauge metal roof often comes down to balancing initial costs against long-term value. While heavier gauges cost more initially, their enhanced durability and reduced maintenance requirements often provide better lifecycle economics for permanent installations.

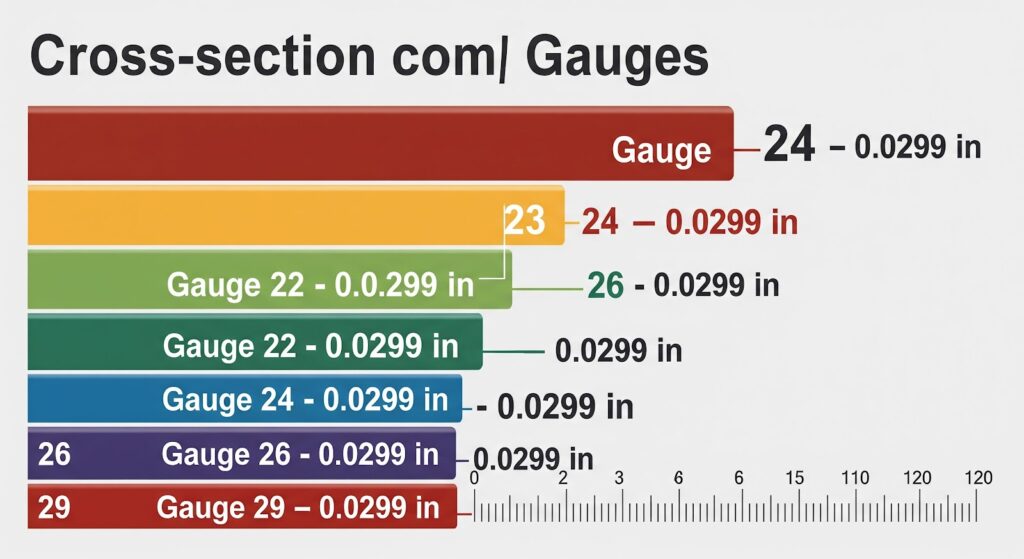

Professional Installation Considerations by Gauge

Thicker gauges require specialized tools and techniques that affect installation costs and contractor selection. Metal roofing gauge chart information should include installation considerations that impact total project costs beyond material pricing.

Heavier gauges provide more installation forgiveness, as their increased strength resists damage from normal handling and fastening operations. Contractors can work more efficiently with thicker materials while achieving better finished appearance and performance.

Thinner gauges demand more careful handling and specialized techniques to prevent installation damage that compromises performance. Professional contractors adjust their methods and tool selection when working with lighter gauges to ensure successful installations.

Fastener selection varies by gauge, with thinner materials requiring different fastener types, spacing, and installation techniques. Proper fastening becomes more critical with lighter gauges to prevent blow-off and ensure adequate structural performance.

Cost Analysis and Value Comparison

Understanding true cost differences helps you make informed decisions about gauge selection based on both initial investment and long-term value considerations. Metal roof thickness affects not just material costs but installation, maintenance, and replacement timing.

Material cost differences between gauges can be substantial, with premium gauges costing 50-100% more than economy options. However, these cost differences must be evaluated against performance differences and expected service life to determine true value.

Installation costs vary less dramatically between gauges, though thinner materials may require more careful handling that increases labor time. Professional contractors factor gauge selection into their pricing to reflect different installation requirements and risk levels.

Long-term costs include maintenance, repair, and eventual replacement expenses that vary significantly between gauge levels. Heavier gauges typically require less maintenance while providing longer service life that improves overall economics despite higher initial costs.

Future-Proofing Your Investment

Metal Roofing Gauge Thickness chart trends show increasing preference for heavier gauges as building owners recognize the value of enhanced durability. Climate change concerns and severe weather frequency increases make thicker gauges more attractive for long-term protection.

Technology improvements in manufacturing and coating systems enhance the value proposition for premium gauges by extending their already superior service life. These advances make quality investments even more attractive for property owners seeking maximum long-term value.

Resale considerations favor quality installations using appropriate gauges over budget approaches that may require early replacement. Real estate professionals recognize the value of quality roofing systems when evaluating property values and marketability.

Frequently Asked Questions

Q1: Is 22 gauge thicker than 24, and how much difference does it make?

Yes, 22 gauge is thicker than 24 gauge by approximately 0.006 inches (22 gauge = 0.0299″ vs 24 gauge = 0.0239″). While this seems small, it represents about 25% more material thickness, which significantly improves dent resistance, structural strength, and longevity. The 22 gauge provides superior performance in hail-prone areas and high-wind zones. For most residential applications, the extra cost of 22 gauge proves worthwhile through reduced maintenance and longer service life, especially in challenging climate conditions.

Q2: What is the best gauge metal roof for residential applications?

The best gauge metal roof for residential use is typically 24 gauge thickness, which provides the optimal balance of performance and cost for most homes. This gauge offers excellent weather resistance, good structural strength, and reasonable pricing. However, homes in severe weather areas benefit from upgrading to 22 gauge for maximum protection, while budget-conscious homeowners in mild climates might consider 26 gauge. The “best” choice depends on your climate, budget, and long-term plans, but 24 gauge satisfies most residential requirements effectively.

Q3: How thick is 26 gauge metal roofing, and is it adequate for my home?

26 gauge metal roofing thickness measures approximately 0.0179 inches. Whether it’s adequate depends on your location and expectations. 26 gauge steel thickness works well for residential applications in moderate climates without severe hail or extreme wind exposure. However, it offers less dent resistance and structural strength than thicker options. If you’re in a hail-prone area, experience frequent severe weather, or want maximum durability, consider upgrading to 24 or 22 gauge for better long-term performance and peace of mind.

Q4: Can I use 29 gauge steel for my roof, and what are the limitations?

29 gauge thickness measures only 0.0135 inches, making it suitable primarily for agricultural buildings, storage sheds, or temporary structures. While how thick is 29 gauge steel makes it the most economical option, it has significant limitations including reduced dent resistance, lower structural strength, and increased susceptibility to thermal movement. For permanent residential applications, 29 gauge generally isn’t recommended due to performance limitations. Most building codes and manufacturer warranties specify minimum gauges heavier than 29 for residential roofing applications.