Choosing the right metal roofing panel sizes is one of the most important steps in planning a durable and cost-effective roofing system. The size of the panels directly affects installation time, material waste, weather resistance, and overall performance.

In this guide, you’ll learn how metal roofing panel sizes work, the standard dimensions available, thickness options, and how to select the best panels for your specific project.

Why Metal Roofing Panel Sizes Matter for Your Project

Metal roofing panel sizes impact more than just appearance. The wrong size can lead to excess overlaps, higher costs, or installation issues. Proper sizing ensures:

-

Better water shedding

-

Fewer seams and leak points

-

Accurate material estimation

-

Faster, cleaner installation

Understanding panel dimensions helps you avoid costly mistakes and choose panels that fit your building perfectly.

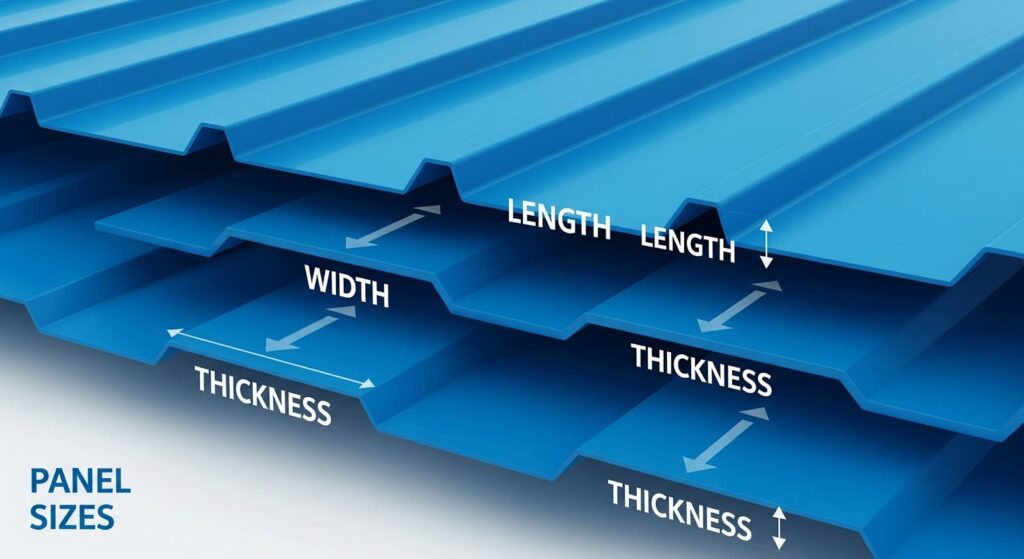

Understanding Metal Roofing Panel Sizes Basics

When discussing metal roofing panel sizes, it’s important to understand what “size” actually means.

Coverage Width vs. Overall Width

-

Overall width: The total edge-to-edge measurement of the panel

-

Coverage width: The usable width after overlaps are accounted for

Always calculate roofing needs based on coverage width, not overall width.

Key Measurements

-

Width: Determines how much roof area one panel covers

-

Length: Affects seam count and water resistance

-

Thickness (Gauge): Influences strength and durability

Standard Metal Roofing Panel Sizes by Width

Most manufacturers offer standardized panel widths for easy planning and installation.

Common Panel Widths

-

12 inches

-

16 inches

-

24 inches

-

26 inches

-

36 inches

Wider panels reduce the number of seams, while narrower panels are easier to handle and install.

Coverage vs. Total Width

A 36-inch panel may only cover 34–35 inches after overlap. Always verify manufacturer specifications before ordering materials.

Metal Roofing Panel Lengths Explained

Panel length is just as important as width when selecting metal roofing panel sizes.

Standard Lengths

-

Typically range from 8 feet to 24 feet

Custom Length Options

Many suppliers offer custom-cut panels to match the roof slope exactly. Benefits include:

-

Fewer horizontal seams

-

Improved leak protection

-

Reduced material waste

Custom lengths are especially useful for long roof spans.

Panel Gauge Thickness Guide

Gauge refers to metal thickness; the lower the gauge number, the thicker the panel.

Common Gauge Options

-

22-gauge: Heavy-duty, ideal for high-wind or commercial buildings

-

24-gauge: Strong and durable, common for standing seam systems

-

26-gauge: Popular for residential roofing due to the balance of strength and cost

-

29-gauge: Lightweight and economical, often used for sheds or agricultural buildings

Selecting the right gauge ensures your panels withstand weather and structural demands.

Metal Roofing Panel Sizes by Type

Different panel styles come in different size profiles.

Corrugated Panels

-

Common profiles: 7/8″ and 1/2″

-

Typically 26″–36″ wide

-

Cost-effective and easy to install

Standing Seam Panels

-

Narrower widths (12″–18″)

-

Designed for concealed fasteners

-

Ideal for modern residential roofs

R-Panels and PBR Panels

-

Usually 36″ wide

-

Common in commercial and industrial buildings

-

Strong rib design for structural support

Ribbed Panels

-

Available in multiple widths

-

Used for both roofing and siding applications

Each panel type has its own sizing standards that affect appearance and performance.

How to Choose the Right Metal Roofing Panel Sizes

Selecting the correct metal roofing panel sizes depends on several factors.

Key Considerations

-

Building type: Homes often use narrower panels; warehouses prefer wider ones

-

Climate: High-wind or snow areas benefit from thicker, longer panels

-

Budget: Larger panels reduce labor but may cost more upfront

Residential vs. Commercial Use

Residential projects prioritize aesthetics and weather protection, while commercial buildings focus on coverage efficiency and structural strength.

Calculating Material Needs

Accurate calculations save time and money.

Panel Overlap and Coverage

Overlaps reduce usable width, so factor this into all measurements.

Estimating Panel Quantity

-

Measure total roof width and length

-

Divide by panel coverage width

-

Add extra panels for waste, cuts, and errors

Correct calculations ensure you order the right amount of material the first time.

Final Thoughts

Understanding metal roofing panel sizes helps you choose panels that fit your roof, budget, and performance needs. By considering width, length, gauge, and panel type, you can confidently select a roofing system that lasts for decades. Whether you’re planning a residential upgrade or a commercial installation, the right panel sizes make all the difference in durability, efficiency, and long-term value.

If you need expert guidance or want help selecting the right panels for your project, contact us today to speak with a knowledgeable roofing specialist and get personalized recommendations for your roof.

Join Our Community

Join our community on Facebook, and don’t forget to subscribe to us on YouTube for new content each week.

FAQs

1. What are standard metal roofing panel sizes?

Most panels come in widths from 12″ to 36″ and lengths between 8 and 24 feet, with custom lengths available for specific roofs.

2. Why does coverage width matter for metal roofing panels?

Coverage width accounts for overlaps and determines the actual roof area each panel covers, helping prevent material shortages.

3. What gauge is best for metal roofing panels?

26-gauge is common for residential roofs, while 24-gauge or 22-gauge is better for commercial or high-wind applications.

4. Can metal roofing panels be custom cut?

Yes, many manufacturers offer custom-cut panels to reduce seams, improve weather resistance, and minimize waste.

5. How do I calculate how many metal panels I need?

Measure roof size, divide by panel coverage width, and add extra panels for overlaps, cuts, and installation waste.