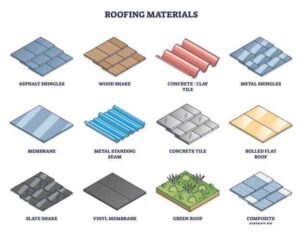

Are you considering a metal roof for your home or business? Whether you’re building a new property or upgrading your current roof, you’re in the right place. Metal roofing is a game-changer when it comes to durability, energy efficiency, and aesthetics. It offers a long-lasting solution that will protect your property for decades, making it a smart investment. But with so many different materials, styles, and components to choose from, it can feel overwhelming. That’s where this guide comes in!

This comprehensive pillar page will cover everything you need to know about metal roofing materials. From choosing the best underlayment for steel roofing to understanding metal roof panel sizes, sealing your metal roof, and more, we’ve got you covered. Plus, we’ll dive into the different components and materials that make up a metal roof to help you make the best choice for your needs.

Let’s get started and help you find the ideal metal roofing system for your project.

1. What is a Metal Roof?

Before we dive into the specifics of metal roofing materials, let’s first define what a metal roof is and why it’s such a popular choice.

A metal roof consists of metal panels or shingles installed on a building’s roof. The material can be steel, aluminum, copper, or zinc, each with its own benefits and costs. Metal roofs are known for their incredible longevity, energy efficiency, and resistance to weather conditions, making them an excellent choice for both residential and commercial buildings.

Why Choose a Metal Roof?

- Longevity: Metal roofs can last 40 to 70 years, far outlasting traditional roofing materials like asphalt shingles (which last about 20 years).

- Durability: Metal roofs can withstand extreme weather conditions, including heavy snow, rain, high winds, and even wildfires.

- Energy Efficiency: They reflect solar heat, which can help reduce your cooling costs during the summer months.

- Environmentally Friendly: Metal roofing is typically made from recycled materials and is also recyclable at the end of its lifespan.

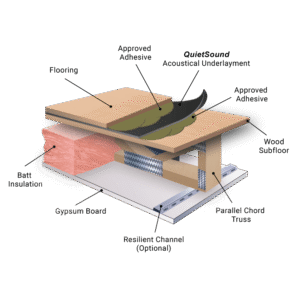

2. Best Underlayment for Steel Roofing

Why Is Underlayment Important?

When installing a steel roof, the right underlayment is just as important as the roof itself. Underlayment is a layer of material installed beneath the roofing panels that adds an extra layer of protection against moisture, leaks, and wind.

Types of Underlayment for Steel Roofing

- Felt Paper Underlayment

- Pros: Economical and easy to install.

- Cons: Not as durable as synthetic options and can deteriorate over time.

- Best For: Mild climates and budget-conscious homeowners.

- Synthetic Underlayment

- Pros: More durable, resistant to UV rays, and provides better moisture protection than felt paper.

- Best For: Areas with harsh weather conditions like heavy rainfall or snow.

- Rubberized Underlayment

- Pros: Excellent waterproofing properties and durability.

- Best For: Areas prone to heavy rains or ice dams.

For steel roofing, synthetic underlayment is often considered the best choice. It’s highly resistant to moisture, UV damage, and provides a strong protective barrier beneath your roofing panels.

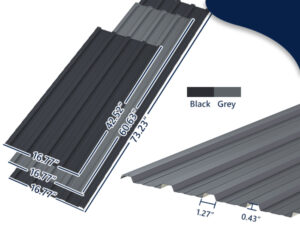

3. Metal Roof Panel Sizes

Understanding Panel Sizes

The size of your metal roof panels is a key factor in determining the overall look and functionality of your roof. Panels come in various lengths and widths, depending on the design and the manufacturer.

- Panel Lengths: Typically range from 6 to 40 feet. Longer panels reduce the number of seams, improving the roof’s water resistance.

- Panel Widths: Range from 12 to 36 inches. Wider panels reduce the number of overlaps, making installation quicker and more efficient.

Choosing the Right Panel Size

For roofs with a steeper pitch, narrower panels may be necessary to ensure proper fit and water runoff. On low-pitched roofs, wider panels are often preferred for a more streamlined appearance.

For more information on panel sizes and how to choose the best one for your project, check out our metal roof panel sizes guide.

4. Best Way to Seal a Metal Roof

Sealing your metal roof is crucial for its long-term performance. Over time, the seams and fasteners can become vulnerable to leaks. Fortunately, there are several effective ways to seal a metal roof.

Methods to Seal a Metal Roof

- Sealant for Seams: Use high-quality roofing sealant around the seams, fasteners, and other vulnerable areas.

- Butyl Rubber Tape: A self-adhesive option that creates a watertight seal on seams and edges.

- Liquid Roof Coating: Applied over the entire roof surface, liquid coatings provide a seamless barrier against water.

Tips for Sealing

- Always clean the roof surface before applying sealant.

- Use UV-resistant sealants to prevent degradation from the sun.

- Apply sealants during dry, warm weather for the best results.

For more information on the best ways to seal your roof, head over to our best way to seal a metal roof page.

5. Best Replacement Screws for Metal Roof

Why Replace Metal Roof Screws?

Over time, the screws used to secure metal roofing panels can loosen, rust, or become damaged. Replacing these screws with the best options available is essential to maintain the roof’s integrity and prevent leaks.

Best Replacement Screws

- Stainless Steel Screws: Highly resistant to rust and corrosion, making them perfect for metal roof.

- Self-Drilling Screws: These screws feature a built-in drill bit, allowing for easier installation without the need for pre-drilling.

- Coated Screws: Screws with a zinc or epoxy coating provide additional protection against corrosion.

For detailed guidance on selecting the best screws, check out our best replacement screws for metal roof guide.

6. How Wide Is Metal Roofing After Overlap?

Understanding Overlap

The overlap is a critical aspect of metal roofing installation. It refers to the way one metal roof panel is laid over another to ensure there are no gaps that could allow water to seep through.

Typically, metal roof panels overlap by 1 to 2 inches. This overlap ensures the panels are properly secured and that the roof remains waterproof.

How Wide Is Metal Roofing After Overlap?

After the overlap, the effective width of a metal roof panel will be slightly reduced. For example, if a panel has a width of 36 inches and overlaps by 1 inch, the effective width of each panel will be 35 inches.

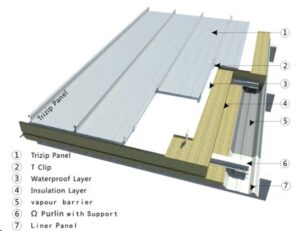

7. Metal Roof Components Diagram

Understanding Metal Roof Components

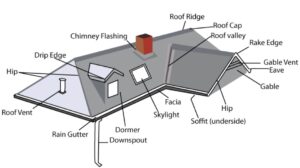

A metal roof is composed of several key components, each of which plays a vital role in ensuring its functionality and durability. These components include:

- Roof Panels: The main material covering the roof.

- Underlayment: A layer of protection beneath the panels.

- Fasteners: Screws or nails used to secure the panels.

- Trim and Flashing: Installed along the edges, ridges, and valleys to prevent water infiltration.

To better understand the components of a metal roof, refer to our metal roof components diagram.

8. Metal Roof Trim Types

What is Metal Roof Trim?

Metal roof trim refers to the finishing pieces used to cover edges, seams, and transitions on a roof. These trims enhance the roof’s appearance while providing additional protection against weather elements.

Types of Metal Roof Trim

- Ridge Caps: Installed at the peak of the roof to cover the ridge and prevent water entry.

- Edge Trim: Installed along the edges of the roof to cover the gap between the roof and walls.

- Sidewall Trim: Used where the roof meets a vertical wall to ensure a tight seal.

Choosing the right trim is essential for both the appearance and performance of your metal roof.

9. Metal Roof Sealant

Why Use Metal Roof Sealant?

A metal roof sealant is used to protect seams and joints from water infiltration. Applying a high-quality sealant ensures that your roof remains waterproof and resistant to leaks.

Types of Metal Roof Sealants

- Butyl Rubber Sealant: Perfect for sealing seams and edges.

- Polyurethane Sealant: Offers excellent adhesion and flexibility.

- Silicone Sealant: Ideal for weather resistance and UV protection.

For a step-by-step guide on how to choose the right metal roof sealant, check out our page on metal roof sealant.

10. Metal Siding Trim Pieces

What Are Metal Siding Trim Pieces?

Metal siding trim pieces are used to frame and finish the edges of metal siding, ensuring that the panels stay secure and that the exterior of your building looks clean and finished.

Types of Metal Siding Trim

- Corner Trim: Used at the corners of the building to provide a neat finish.

- J-Channel Trim: Fitted around windows and doors for a seamless look.

- Base Trim: Installed at the base of the wall to protect against moisture.

Learn more about these trims by visiting our metal siding trim pieces page.

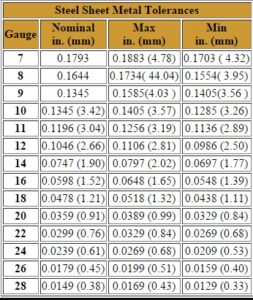

11. 24 Gauge Thickness

What is 24 Gauge Metal?

24 gauge refers to the thickness of the metal used in roofing and siding materials. The lower the gauge number, the thicker the metal. 24 gauge metal is thicker and more durable than 26 gauge metal.

Benefits of 24 Gauge Metal

- Durability: 24 gauge metal is highly resistant to denting and impact.

- Longevity: It provides excellent protection against extreme weather conditions.

- Strength: This thickness is ideal for areas that experience heavy winds, snow, or rain.

For more information on 24 gauge metal, refer to our 24 gauge thickness guide.

Conclusion: Why Metal Roofing is a Smart Investment

In conclusion, metal roofing is a smart and long-term investment for any homeowner or business owner. From its unparalleled durability and energy efficiency to its eco-friendliness and low-maintenance requirements, metal roofing offers a wide range of benefits. Understanding the materials, components, and installation techniques is crucial to ensuring that your roof performs at its best for years to come.

Ready to Get Started?

Now that you know all about metal roof materials, it’s time to make an informed decision. Whether you’re ready to start your project or still need some guidance, don’t hesitate to contact a professional roofer. They’ll help you choose the best materials, sealants, and underlayment for your needs and install your metal roof with precision.

If you’re looking for more in-depth information on any of the subtopics mentioned in this guide, check out our detailed subpages. We’ve got all the answers you need to make the best choices for your metal roof project!