If you’re considering installing or maintaining a metal roof, one crucial step that can’t be overlooked is sealing. Proper sealing ensures that your roof remains watertight, resistant to the elements, and free from leaks. Whether you’re installing a brand-new metal roof or fixing up an existing one, knowing the best way to seal a metal roof is key to ensuring its longevity and performance.

In this guide, we’ll explore the different sealing methods, including metal roof screw sealant, overlap sealants, and how to properly seal your tin roof. Plus, we’ll give you expert tips and practical advice to help you choose the best products for your project.

1. Why Sealing Your Metal Roof is Essential

Before we dive into the specifics, let’s first understand why sealing is so important for metal roofs. Unlike traditional roofing materials, metal roofs are highly durable and weather-resistant. However, they still have seams, joints, and fasteners where water can seep through if not properly sealed.

Benefits of Sealing a Metal Roof:

- Prevents Leaks: The primary purpose of sealing a metal roof is to prevent water from infiltrating through seams and fasteners.

- Enhances Durability: Sealing extends the life of your roof by protecting it from rust, corrosion, and weather damage.

- Improves Energy Efficiency: Some sealants also provide thermal insulation, which can help reduce energy bills by keeping your home cooler.

- Reduces Maintenance: Properly sealing your roof reduces the chances of leaks, which means fewer repairs and lower maintenance costs.

Now that we understand the importance of sealing, let’s look at the best way to seal a metal roof and the methods you can use.

2. The Best Way to Seal a Metal Roof: Step-by-Step

The process of sealing a metal roof can vary depending on the type of roof, its condition, and the materials used. Below, we’ll walk you through the most effective sealing methods for your metal roofing project.

1. Start with Cleaning Your Roof

Before applying any metal roof overlap sealant or other sealing materials, it’s crucial to clean the surface of your roof. Dirt, debris, and old sealant can interfere with the new sealant’s ability to bond and create a watertight seal.

How to Clean a Metal Roof:

- Remove Debris: Use a broom or leaf blower to clear leaves, dirt, and twigs from the roof.

- Wash the Surface: Use a pressure washer or hose to remove grime and buildup. For tough stains or rust spots, use a mild cleaning solution or metal roof cleaner.

- Let the Roof Dry: Ensure the surface is completely dry before applying any sealants. Moisture can prevent the sealant from adhering properly.

2. Apply the Best Metal Roof Screw Sealant

One of the most common places where leaks occur in metal roofs is around the screws. Metal roof screw sealant is specifically designed to protect the screws and fasteners from moisture infiltration.

How to Apply Metal Roof Screw Sealant:

- Choose the Right Sealant: Look for a high-quality metal roof screw sealant that is designed for outdoor use and is resistant to UV rays and weathering.

- Apply Generously: Using a caulking gun or tube, apply the sealant around each screw and fastener. Be sure to cover the entire screw and surrounding area to create a watertight seal.

- Smooth Out Excess Sealant: Use a putty knife or your finger to smooth out the excess sealant around the screws for a clean finish.

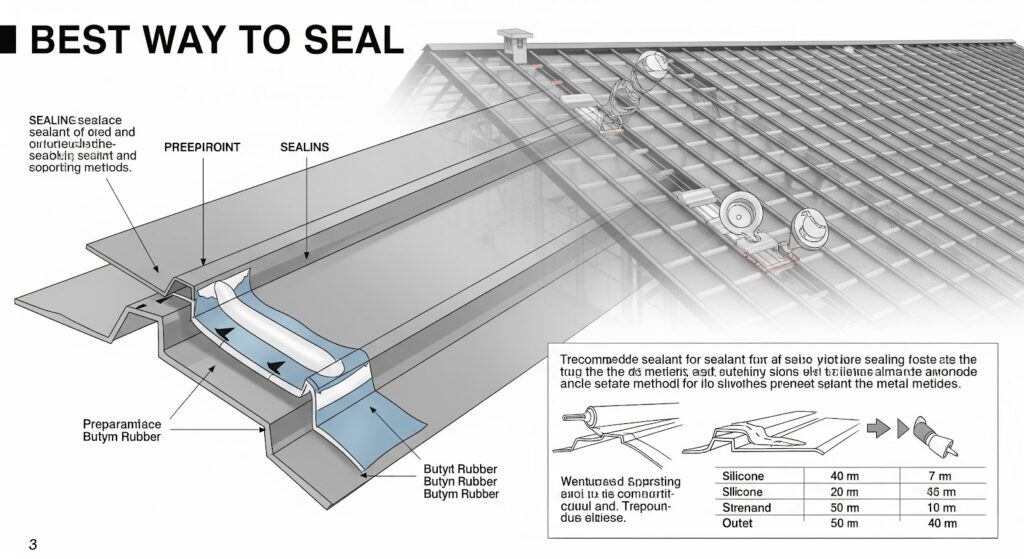

3. Seal the Overlaps with Metal Roof Overlap Sealant

Metal roofing panels often overlap to prevent water from seeping in between them. Metal roof overlap sealant is designed to seal these seams and overlaps, ensuring no water gets through.

How to Seal Metal Roof Overlaps:

- Choose a Quality Overlap Sealant: Select a metal roof overlap sealant that is designed to create a flexible, waterproof seal between metal panels.

- Apply the Sealant: Apply a bead of sealant along the edge of the overlap, making sure it covers the entire seam. Be generous with the application to ensure full coverage.

- Smooth the Sealant: Use a putty knife or a brush to smooth the sealant along the seam. This helps remove air bubbles and ensures even coverage.

- Allow to Cure: Let the sealant cure according to the manufacturer’s instructions, usually for 24-48 hours, before exposing the roof to rain.

4. How to Seal a Tin Roof

Tin roofing, which is typically made from corrugated steel or galvanized steel, requires a slightly different approach. Tin roof sealing focuses on sealing the seams and fasteners to prevent rust and leaks.

Steps to Seal a Tin Roof:

- Clean the Roof: As with all metal roofs, start by cleaning the surface of the tin roof. Remove debris and dirt to ensure the sealant adheres properly.

- Apply a Metal Roof Sealant: Use a metal roof membrane or silicone sealant that is designed for tin roofs. This type of sealant is typically UV-resistant and provides long-lasting protection.

- Seal the Seams and Fasteners: Apply sealant generously to the seams, joints, and screws. Ensure that the fasteners are fully covered to create a watertight seal.

- Check for Leaks: Once the sealant has cured, test your roof for leaks by spraying water over the surface or checking for any signs of water infiltration.

5. Use a Liquid Roof Coating for Extra Protection

For an additional layer of protection, consider applying a liquid roof coating after sealing the seams and fasteners. Liquid roof coatings provide a seamless, waterproof membrane that helps protect the entire surface of your metal roof from the elements.

How to Apply Liquid Roof Coating:

- Select the Right Coating: Choose a metal roof coating that is designed for outdoor use and offers UV resistance, waterproofing, and rust prevention.

- Apply the Coating: Using a roller or brush, apply the liquid coating evenly across the surface of the roof. Work in small sections to ensure full coverage.

- Allow to Cure: Let the liquid roof coating dry completely before subjecting the roof to weather conditions.

3. Tips for Maintaining Your Sealed Metal Roof

Once your metal roof is sealed, it’s essential to maintain it to ensure long-term protection. Here are a few tips to keep your metal roof in top condition:

- Inspect Regularly: Check for any signs of wear, including cracks, peeling, or areas where the sealant has worn off. Inspect the screws and fasteners regularly to ensure they remain sealed.

- Clean Your Roof Periodically: Keep your metal roof clean to prevent buildup of debris, which can cause moisture retention and damage to the sealant.

- Reapply Sealant as Needed: Depending on the conditions in your area, you may need to reapply sealant every 5-7 years to maintain the roof’s waterproofing.

4. Conclusion: Seal Your Metal Roof for Maximum Protection

When it comes to sealing your metal roof, the right products and techniques can make all the difference. By using the best way to seal a metal roof, such as metal roof screw sealant, metal roof overlap sealant, and tin roof sealing methods, you can ensure that your roof stays waterproof, durable, and energy-efficient for years to come.

Ready to Seal Your Roof?

If you’re ready to tackle your metal roofing project, follow the steps outlined in this guide to apply the best sealant for metal roofs. Whether you’re dealing with a tin roof or a standing seam metal roof, the right sealing method will help protect your investment and extend the life of your roof.

Don’t wait for leaks to start showing up. Seal your roof today and enjoy peace of mind knowing your home is protected from the elements!

If you’re looking for high-quality sealants and roofing products, contact a trusted roofing supplier or contractor who can provide expert recommendations and top-notch products for your project.